Planetary Ball Mill 4x100 ml

4.235,00€ 4.500,00€

The planetary ball mill is a small and easy-to-use laboratory ball mill for fine grinding, mixing, homogenisation, mechanical alloying, cell disruption, small sample preparation, new product development and small volume high-tech material production.

The planetary ball mill is characterised by its small volume, high efficiency, fast clamping and quiet operation. The system can be used to grind various materials down to 0.1 µm. It can also be used to grind and mix various products of different materials and particle sizes in dry or wet process.

The planetary ball mill is widely applied in the fields of geology, mining, metallurgy, electronics, building materials, ceramics, chemical engineering, light industry medicine, environmental protection, etc.

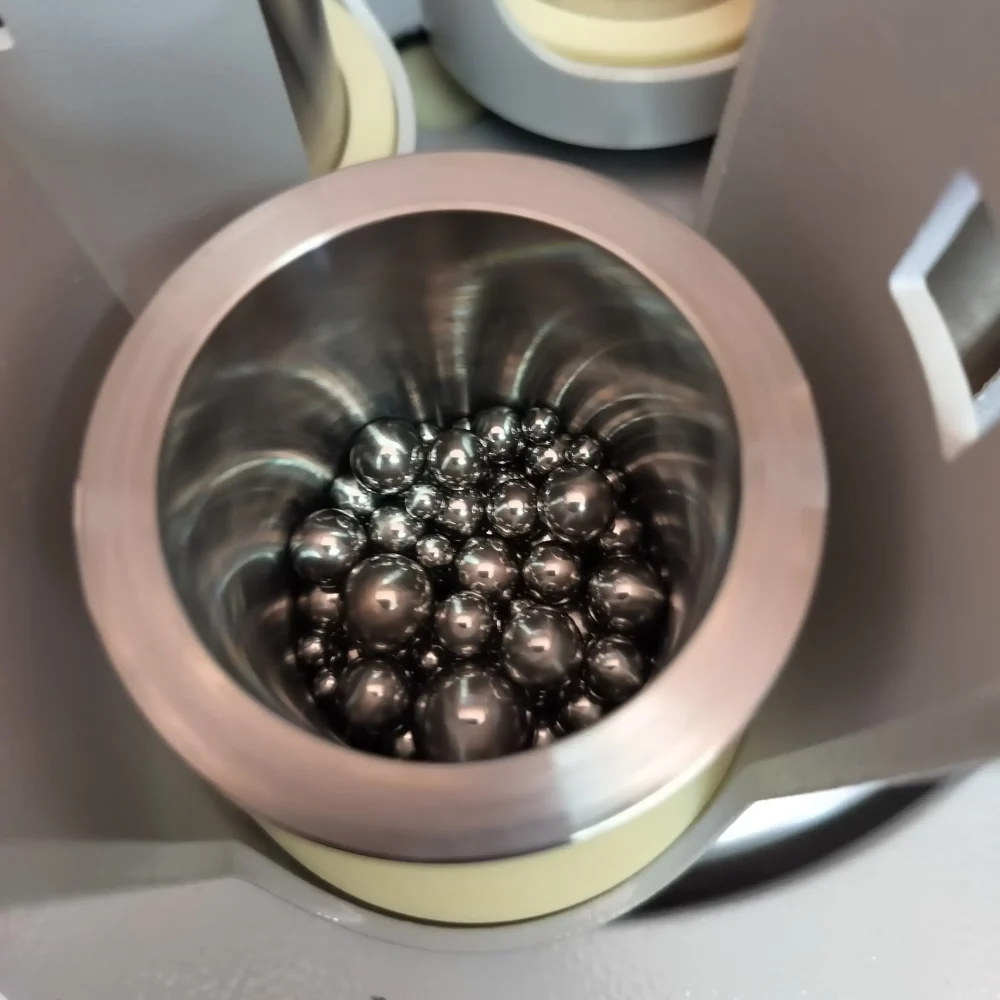

Vessels and balls made of various materials such as Teflon, nylon, stainless steel, abrasion resistant steel, tungsten carbide, agate, sintered corundum and zirconium oxide can be used.

As standard, the equipment comes with a kit of 4 containers and 4 stainless steel ball kits. If you require a different specification please contact info@ipsilonlabs.com

| Weight | 50 kg |

|---|---|

| Brand | BIOBASE |

| Material | Metal |

| Product type | Instrument, Mill, Ball mill |

Description

The planetary ball mill is a small and easy-to-use laboratory ball mill for fine grinding, mixing, homogenisation, mechanical alloying, cell disruption, small sample preparation, new product development and small volume high-tech material production.

The planetary ball mill is characterised by its small volume, high efficiency, fast clamping and quiet operation. The system can be used to grind various materials down to 0.1 µm. It can also be used to grind and mix various products of different materials and particle sizes in dry or wet process.

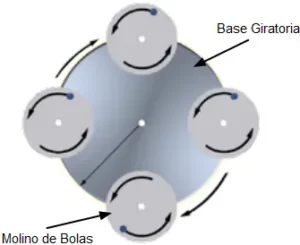

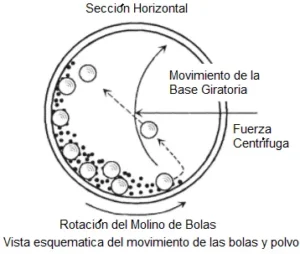

The planetary ball mill is based on a system of several ball mills (placed on a rotating base as shown in the figure below) which are filled with balls. Two rotational motions move the ball mills. As in a planetary system, the mills rotate in an orbit around a centre. This rotational motion generates the automatic movement of the mills. The resulting centrifugal action and acceleration force achieves an efficient grinding action. There are forces acting according to the Coriolis acceleration force. The result is intensive grinding between the ball mill and the sample.

|

|

There are different rotation ratios. With a rotation ratio of 1:-2, the mill rotates twice during one revolution of the rotating base. The negative sign in this case indicates the opposite direction of rotation. Depending on the rotation speed, either the balls cross the vessel in the middle and hit the sample against the inner wall of the vessel weakening its resistance or, in a different speed pattern, the balls roll over the sample and weaken the ground material.

The selection of the ball vessel material and the correct filling level has a great impact on the grinding result. Depending on the application, the correct quantity (volume) and material of the mill and media must be selected. The filling consists of approximately 1/3 of the sample and 1/3 of the ball charge. The remaining third is a free volume, which is necessary for the movement of the media. The following table gives some recommendations.

| Material | Hardness | Density (g/cm3) | Wear resistance | Potential residual sample contamination |

| Nylon | Elastic, D75 (Shore) | 1,14 | Low | C |

| Teflon | Elastic, D56 (Shore) | 2,2 | Low | F, C |

| Stainless steel | 550 HV | 7,8 | Medium | Fe, Cr, C |

| Wear-resistant steel | 750 HV | 7,8 | Medium | Fe, Cr, C |

| Agate | 1.000 HV | 2,55-2,91 | Medium | Si |

| Sintered aluminium oxide (Al2O3) | 1.750 HV | 3,9 | High | Al, Si |

| Zirconium oxide (ZrO2) | 1.200 HV | 5,6-6,0 | High | Zr, Y |

| Tungsten carbide | 1.200 HV | 14,6-14,9 | High | W, C |

FEATURES AND BENEFITS

- High milling efficiency for a product down to <0,1 µm

- Different speed ratios available

- Ball mills from 50 ml to 100 ml in different materials

- Suitable for long tests and continuous use

- Reversible automatic steering to avoid material buildup

- Programmable milling parameters

Planetary ball mill vessels are constructed from a single piece of the specified material. The advantages of the vessels are:

- Easy opening according to the aperture between the rim and the grinder

- Easy self-centering ball mill base

- Hermetic seal to avoid gas and dust contamination

Applicable to samples such as soil, wood fibres, plants, seeds, tobacco, bentonite, cement, gypsum, sand, stone, hair, bone, coal, paints and lacquers, catalysts, pigments, glass, hydroxyapatite, kaolin, ceramic oxides, quartz, clay, minerals, semi-precious stones, rapeseed, coke, alloys, metal oxides, slag, electronic waste, sludge, organic and inorganic waste and others. Some samples require pre-treatment such as drying.

-

- CONTENT

- Planetary Ball Mill 4x100 ml

- 4x stainless steel milling vessels

- 4x stainless steel ball kit

- Power supply cable

- User manual in English

- CE conformity marking

- CONTENT

-

- SPECIFICATIONS

Power and voltage 220 V AC – 50 Hz – 250 W Operating principle Impact / Friction Operation mode 2 or 4 grinding stations simultaneously Vacuum grinding option Yes Grinding ball size ⌀ 5, ⌀8, ⌀10, ⌀12, ⌀15 mm Max. capacity 2/3 of the container (including balls) Maximum particle size Fragile materials <10 mm Rest < 4 mm

Discharge particle size Up to 0.1 µm Speed control Yes Time control Yes Reverse rotation Yes Programmable method Yes Max. noise 58 dB Dimensions, cm 50x30x34 Weight, kg 29 kg without vessels

- SPECIFICATIONS

You can request the following technical documents at info@ipsilonlabs.com:

- User manual in English

- CE conformity marking